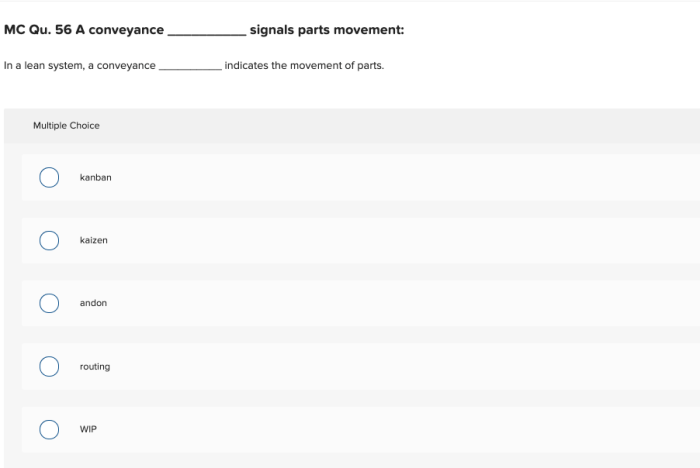

A conveyance __________ signals parts movement. – Conveyance Mechanisms: Signaling Parts Movement explores the intricate relationship between conveyances and the movement of parts. By examining various conveyance types, parts movement mechanisms, and signaling systems, this discourse unravels the complexities of efficient and effective parts handling within industrial and manufacturing settings.

The intricate interplay between conveyances and parts movement forms the cornerstone of this discussion, delving into the diverse mechanisms employed to initiate, control, and monitor the movement of parts within a conveyance system. Moreover, the design considerations that shape conveyance effectiveness are meticulously examined, highlighting the impact of factors such as speed, capacity, and efficiency.

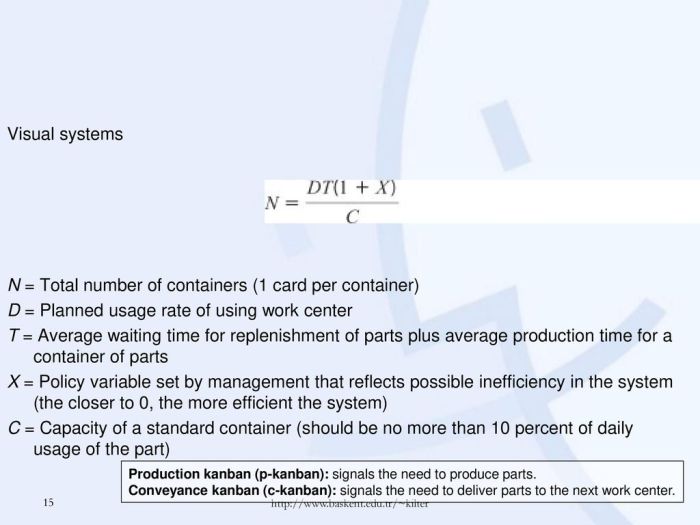

Types of Conveyances

Conveyances are devices that move parts within a manufacturing or assembly system. They can be used to transport parts between workstations, to feed parts into machines, or to remove parts from machines. There are many different types of conveyances, each with its own advantages and disadvantages.Some

of the most common types of conveyances include:

- Belt conveyors:Belt conveyors use a continuous belt to move parts. They are simple to operate and maintain, and they can be used to transport parts of all shapes and sizes.

- Chain conveyors:Chain conveyors use a chain to move parts. They are more durable than belt conveyors, but they are also more expensive.

- Roller conveyors:Roller conveyors use rollers to move parts. They are less expensive than belt or chain conveyors, but they are not as durable.

- Overhead conveyors:Overhead conveyors use a track to move parts. They are more expensive than other types of conveyances, but they are also more efficient.

- AGVs (Automated Guided Vehicles):AGVs are self-propelled vehicles that can be programmed to move parts along a predetermined path. They are more expensive than other types of conveyances, but they are also more flexible.

The type of conveyance that is used in a particular application will depend on the specific requirements of the application.

Parts Movement Mechanisms: A Conveyance __________ Signals Parts Movement.

Parts can be moved within a conveyance using a variety of mechanisms. The most common mechanisms include:

- Linear motion:Linear motion is used to move parts in a straight line. This can be accomplished using a belt, chain, or roller conveyor.

- Rotary motion:Rotary motion is used to move parts in a circular motion. This can be accomplished using a turntable or a carousel.

- Reciprocating motion:Reciprocating motion is used to move parts back and forth. This can be accomplished using a piston or a cam.

The type of parts movement mechanism that is used in a particular application will depend on the specific requirements of the application.

Signals for Parts Movement

Parts movement within a conveyance can be initiated or controlled using a variety of signals. The most common types of signals include:

- Electrical signals:Electrical signals are used to control the movement of motors and other electrical devices.

- Mechanical signals:Mechanical signals are used to control the movement of mechanical devices, such as levers and cams.

- Optical signals:Optical signals are used to control the movement of parts using light.

- Pneumatic signals:Pneumatic signals are used to control the movement of parts using air pressure.

- Hydraulic signals:Hydraulic signals are used to control the movement of parts using fluid pressure.

The type of signal that is used in a particular application will depend on the specific requirements of the application.

Conveyance Design Considerations

When designing a conveyance, there are a number of factors that must be considered. These factors include:

- Speed:The speed of the conveyance will determine how quickly parts can be moved.

- Capacity:The capacity of the conveyance will determine how many parts can be moved at one time.

- Efficiency:The efficiency of the conveyance will determine how much energy is required to move parts.

- Reliability:The reliability of the conveyance will determine how often it breaks down.

- Cost:The cost of the conveyance will determine how much it will cost to purchase and operate.

The design of the conveyance will also be affected by the type of parts that are being moved. For example, a conveyance that is used to move heavy parts will need to be more durable than a conveyance that is used to move light parts.

Maintenance and Troubleshooting

Conveyances require regular maintenance to ensure that they are operating properly. Some of the most common maintenance tasks include:

- Inspecting the conveyance for wear and tear.

- Lubricating the moving parts.

- Tightening the bolts and screws.

- Replacing worn parts.

If a conveyance breaks down, it is important to troubleshoot the problem and make repairs as quickly as possible. Some of the most common problems that can occur with conveyances include:

- The conveyance is not moving.

- The conveyance is moving too slowly.

- The conveyance is moving too quickly.

- The conveyance is making noise.

- The conveyance is leaking fluid.

If you are unable to troubleshoot the problem yourself, you should contact a qualified technician.

Popular Questions

What are the different types of conveyances used in parts movement?

Conveyances encompass a wide range of equipment, including conveyors, cranes, hoists, and automated guided vehicles (AGVs), each tailored to specific parts movement requirements.

How do signaling mechanisms control parts movement?

Signaling mechanisms, such as sensors, encoders, and programmable logic controllers (PLCs), provide real-time data and control signals to initiate, regulate, and monitor parts movement within a conveyance system.

What are the key design considerations for effective conveyance systems?

Effective conveyance systems demand careful consideration of factors such as speed, capacity, efficiency, and safety, ensuring optimal performance and minimizing downtime.